Innovative Techniques for Enhancement of Safety of Roadway Bridge Girders using Noncorrosive Advanced Composite Materials

An ongoing research at the Emirates Center for Mobility Research (ECMR) of UAEU that aims at enhancing the safety of roadway bridges by implementing innovative strengthening techniques to steel girders as the main structural element in bridges. An Extensive experimental program was carried out on a total of 49 large scale steel girders with various strengthening configurations to boost their flexural capacity. Tested girders were strengthened by attaching hybrid fiber-reinforced polymer (HFRP) strips to the tension flanges using steel and FRP fasteners. This approach targets overcoming the undesirable brittle failure of the traditional strengthening techniques which involves bonding the FRP strips to the steel girders using bonding materials/epoxies.

The experimental program comprises two main phases depending on the fastener material.

The first phase utilized steel fasteners to investigate the effects of HFRP length,

HFRP thickness, fasteners arrangements, and fasteners spacing on the performance of

strengthened girders. Meanwhile, FRP fasteners were adopted in the second phase to

examine the effects of fasteners material, fasteners spacing, and HFRP thickness on

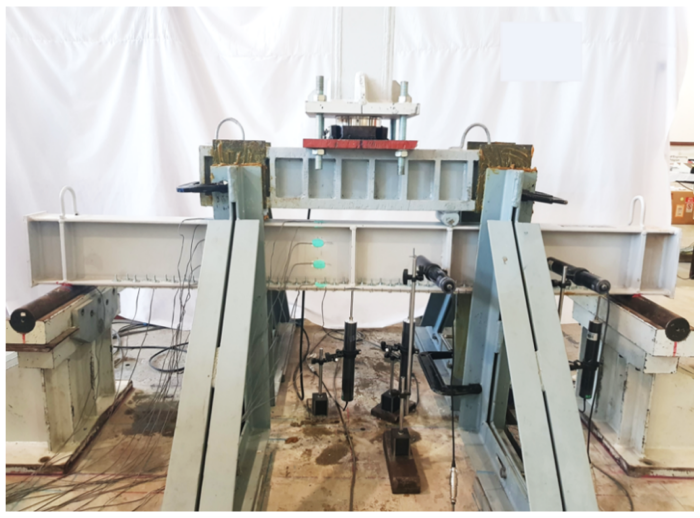

the response. The strengthened girders were tested in four-point loading set-up in

a displacement-controlled manner with a rate of 1.5 mm/min in order to capture the

post-peak response of the fastened assemblies. All girders were equipped by electrical

resistant strain gauges and LVDTs to enable detailed analysis of the performance of

the fastened system.

Fig. 1: Experimental test set-up

Strengthened girders failed in a ductile manner while experiencing combination of failure mechanisms including flange local buckling, girder lateral torsional buckling and bearing between the fasteners and the HFRP strips. Meanwhile, the overall performance of the fastened configurations was assessed by analyzing the load-deflection relations as compared to control un-strengthened girders. The adopted fastening technique proved its efficiency in enhancing the yield and ultimate load carrying capacities of the strengthened girders by 12% and 22 %, respectively. The findings of this research offer the structural designers the required guidelines to adopt the fastening technique in strengthening the steel girders while maintaining ductile behavior of the system.

Fig. 2: Fastened HFRP strip using steel fasteners

Detailed numerical simulations are currently developed using ANSYS software to allow for in-depth analysis of the system. The developed models will be used to enlarge the database for the designers through examining a wider range of fastening parameters. Results of the analysis will be utilized to propose practical configurations to achieve optimum performance of steel girders strengthened by fastened HFRP strips.

Fig. 3: Numerical stresses displayed by ANSYS

Contributors:

- Amr Sweedan (Director of Academic Affairs, Office of the Provost and Associate Professor, Department of Civil and Environmental Engineering)

- Omnia R. Abou El-Hamd (Research Assistant, ECMR)

Do you find this content helpful?

عفوا

لايوجد محتوى عربي لهذه الصفحة

عفوا

يوجد مشكلة في الصفحة التي تحاول الوصول إليها